Esperanza: A diamond unlike any other

Cutting and polishing Esperanza

Since it came out of the ground in Arkansas, there was no question Esperanza had to be cut there, specifically at Stanley Jewelers Gemologist in North Little Rock. It was also decided we would create an in-store event around the cutting process. From Sept. 9 to 12, Mike would cut the diamond at his bench, which we shipped from our home base in Prince Albert, Sask.

Sept. 8

Mike’s first task upon arriving at Stanley Jewelers was to study Esperanza to determine the exact location of its various crystal planes. After examining it, he decided to cut the initial facet close to the transition point between 100, 110, and 111. This meant one of the larger facets would be very close to 111, which is the hardest plane on a diamond, and on Esperanza, one that would come to haunt him later.

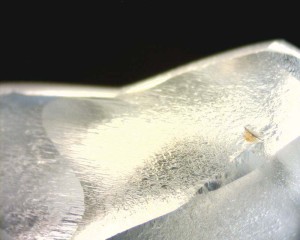

“Fortunately, I had about 1.5 degrees in my favour off this plane,” Mike notes. “First, I wanted to remove a protrusion to improve the possibility of clamping the diamond properly for cutting and to confirm the cutting direction. It also allowed me to create a window to look into the diamond.”

Excluding the team at AGS Laboratories, no less than seven AGS-certified gemmologists and gemmologist appraisers had viewed Esperanza and could not find any inclusions. Note the tiny orange surface blemish on the right side of this photo. This was the only visible imperfection on Esperanza. In addition to shipping the polishing bench to Arkansas and all the tools Mike would need, we were fortunate to have a diamond scanner on hand to confirm the position of the first facet. Cutting a diamond’s first facet is a crucial part of the process, as it serves as the foundation or reference facet to which all the others will be inclined and indexed.

While cutting the subsequent facets, Mike juggled media interviews and photo sessions featuring Brooke Oskarson, the woman who had discovered Esperanza, as well as our hosts, the Stanley family. Not much work got done that day, but the atmosphere in the store was filled with awe and expectation. It seemed the whole of Arkansas was following what we were doing.

Sept. 9

Cutting started in earnest at 7 a.m. and Mike began by profiling Esperanza to establish the diamond’s precise outline. This is a complex procedure, as it involves checking and rechecking every detail. Imagine cutting three emeralds and six trapezoids in combination. If anyone thinks achieving an emerald cut is easy because it comprises straight lines, think again! Getting those lines absolutely parallel is the ultimate test of excellence in diamond polishing. Throughout the day, Mike answered questions and posed Esperanza for photos, as well as ensured the YouTube live stream we had set up kept about 2000 viewers from 95 countries engaged. Work continued throughout the day and finished at 6 p.m. for a total of 11 hours at the bench.